M.TECH. ADVANCED MANUFACTURING SYSTEMS

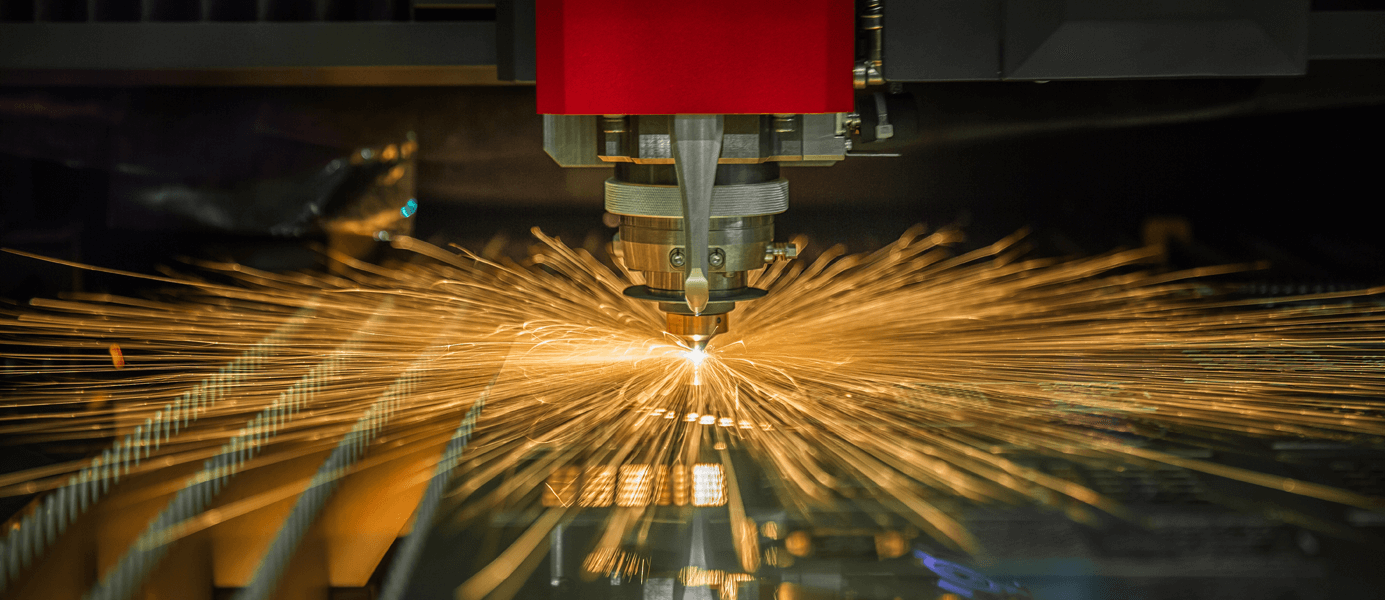

The M. Tech in Advanced Manufacturing Systems at SR University, Warangal is designed to equip graduates with in-depth knowledge and advanced technical expertise in modern manufacturing technologies. The program focuses on the integration of automation, digital manufacturing, additive manufacturing, precision engineering, and smart production systems aligned with the principles of Industry 4.0. Students will gain a strong foundation in the design, optimization, and control of manufacturing processes supported by cutting-edge tools such as IoT, Artificial Intelligence (AI), Machine Learning (ML), and data analytics. The curriculum emphasizes research-driven learning and industrial relevance, enabling students to develop innovative solutions for real-world manufacturing challenges. Learners are encouraged to explore advanced topics like sustainable manufacturing, flexible automation, CAD/CAM integration, and advanced materials processing, ensuring they stay ahead in an evolving industrial landscape. Through state-of-the-art laboratories, collaboration with industry partners, and engagement with SRU’s Center for Materials & Manufacturing (CMM), students gain hands-on exposure to advanced manufacturing tools and research projects. The program nurtures analytical thinking, problem-solving skills, and innovation, preparing graduates for leadership roles in manufacturing, R&D, automation, and industrial engineering. Graduates of this program are well-positioned to contribute to smart factories, aerospace, automotive, defense, and emerging technology sectors, or to pursue doctoral research in advanced manufacturing domains..

2 years (4 semesters)

Research-Driven and Project-Based Learning: Focused on solving real-world industrial challenges through research-oriented, project-based learning in collaboration with the Center for Materials & Manufacturing (CMM).

Advanced and Industry-Aligned Curriculum: Offers specialized courses in Smart Manufacturing & Industry 4.0, Digital Twin in Manufacturing, Advanced Manufacturing Processes, Additive Manufacturing & Surface Engineering, and Sustainable and Precision Manufacturing.

Hands-on Experience in Modern Labs: Provides practical training in CNC machining, 3D printing, and digital manufacturing systems using state-of-the-art facilities.

Flexible Learning Pathways: Enables students to customize their learning based on interests in automation, materials processing, or computational manufacturing.

Interdisciplinary Exposure: Promotes collaboration with domains like Electronics, Computer Science, and AI to integrate IoT, data analytics, and machine learning in manufacturing systems.

Expert Faculty and Mentorship: Guided by experienced faculty and researchers specializing in advanced manufacturing, smart systems, and materials engineering.

Internships and Industry Collaboration: Offers industry internships and live projects through partnerships with SRiX and leading industrial and R&D organizations.

Manufacturing Engineer

Process Development Engineer

Production Planning & Control Engineer

Additive Manufacturing (3D Printing) Engineer

CNC Programming and Machining Specialist

Quality and Reliability Engineer

Product Design & Development Engineer

Industrial Automation Consultant

Sustainability & Smart Factory Engineer

Research and Development (R&D) Engineer

Data Analyst / AI Specialist (Manufacturing Focus)

Maintenance & Reliability Engineer

Project Engineer

Tool Design Engineer

Industrial Engineer

Supply Chain & Manufacturing Systems Analyst

Academic / Research Associate

Aerospace and Defense Manufacturing

Precision Engineering and Tooling

Industrial Automation and Robotics

Additive Manufacturing and 3D Printing Startups

Electronics and Semiconductor Manufacturing

Energy and Renewable Systems

Research & Development Laboratories

Smart Factory and Digital Manufacturing Enterprises

Program Educational Objectives (PEO) 1: Apply mathematics, science, engineering, and IT tools to analyze, design, and evaluate advanced manufacturing processes, while focusing on management principles to execute interdisciplinary projects with professionalism, ethical responsibility, leadership, and a strong commitment to sustainability.

Program Educational Objectives (PEO) 2: Develop technologies to solve real-world manufacturing engineering problems, contributing to sustainable industrial growth and societal development.

Program Educational Objectives (PEO) 3: Pursue lifelong learning to adapt to emerging technologies and evolving industry needs, ensuring continuous professional growth and advancement.

PO1: Ability to apply the knowledge of Science, Mathematics and Engineering principles for developing critical thinking and problem-solving skills.

PO2: Ability to independently carry out research /investigation, development work to solve practical problems and to write / present a substantial technical report.

PO3:Ability to function as a member of a multidisciplinary team with sense of ethics, integrity, and social responsibility.

PO4: Students will be able to demonstrate technical competence in the design of products, processes, and systems to address identified problems through focused research based on technical documentation and evaluation principles.

PSO1: Students will apply their engineering skills in corporate and government settings to satisfy current stakeholder needs, ultimately contributing to social growth.

PSO2: Students should be able to demonstrate a degree of mastery over the area of Advanced Manufacturing Systems.

Advanced manufacturing industries "increasingly integrate new innovative technologies in both products and processes".

It involves simulation, physical and computer modeling, advanced production technologies, and control techniques.

Advanced manufacturing includes advanced robotics and other intelligent production systems, Computer aided analysis, process controls and quality systems.

State-of-the-art Lab facilities are available for design and manufacturing.

The program focuses on inculcating research capabilities in the advanced materials and manufacturing areas.

Post Graduates are well trained to be effective academicians and researchers.

Highly qualified faculty from premier institutes like NITs’ and IITs’.

Job opportunities are available in public and private sectors. The Post Graduates will be ready for: teaching in Academic Institutions, challenging jobs in industry, establishing their own ventures etc. In addition, there are wide opportunities to carry out research in national and International R&D Institutes as well as Doctoral Fellow (Ph.D-Research).