B.TECH. MECHANICAL ENGINEERING

The 4-year, NBA-accredited B. Tech in Mechanical Engineering at SR University blends strong fundamentals—design, mechanics, manufacturing, materials, thermal-fluids, and controls—with the technologies shaping modern industry: Smart Manufacturing & Industry 4.0, IoT, AI/ML, Robotics & Automation, Renewable Energy, EV/Automotive systems, and sustainable engineering. Learning is project-based and hands-on, with maker-spaces, hackathons, and frequent industry-led workshops anchoring theory to real applications. You’ll build, test, and iterate in advanced labs and fabrication facilities; pursue flexible pathways with the option to sequence select courses; and add minors across departments (e.g., Entrepreneurship, Industry 4.0) to sharpen your career edge. Signature offerings include 3D Printing / Additive Manufacturing, Nanomaterials, Robotics & Automation, Mechatronics, and Drone Technology trainings aligned to current employer needs. Through the iScholars program at the Center for Materials & Manufacturing (CMM) and other interdisciplinary centers @SRU, students lead live projects, publish, and prototype. Internships through SRiX and partner industries/research labs, along with an industry-guided capstone, ensure graduates are job-ready for roles in manufacturing, automotive/EV, aerospace, energy, R&D, and smart factory operations—with the entrepreneurial mindset to turn ideas into products and start-ups.

4 years (8 semesters)

NBA-accredited program

Future-ready: Smart Manufacturing, Industry 4.0, IoT/AI-ML, EVs

Project-based learning with maker-spaces, hackathons, competitions

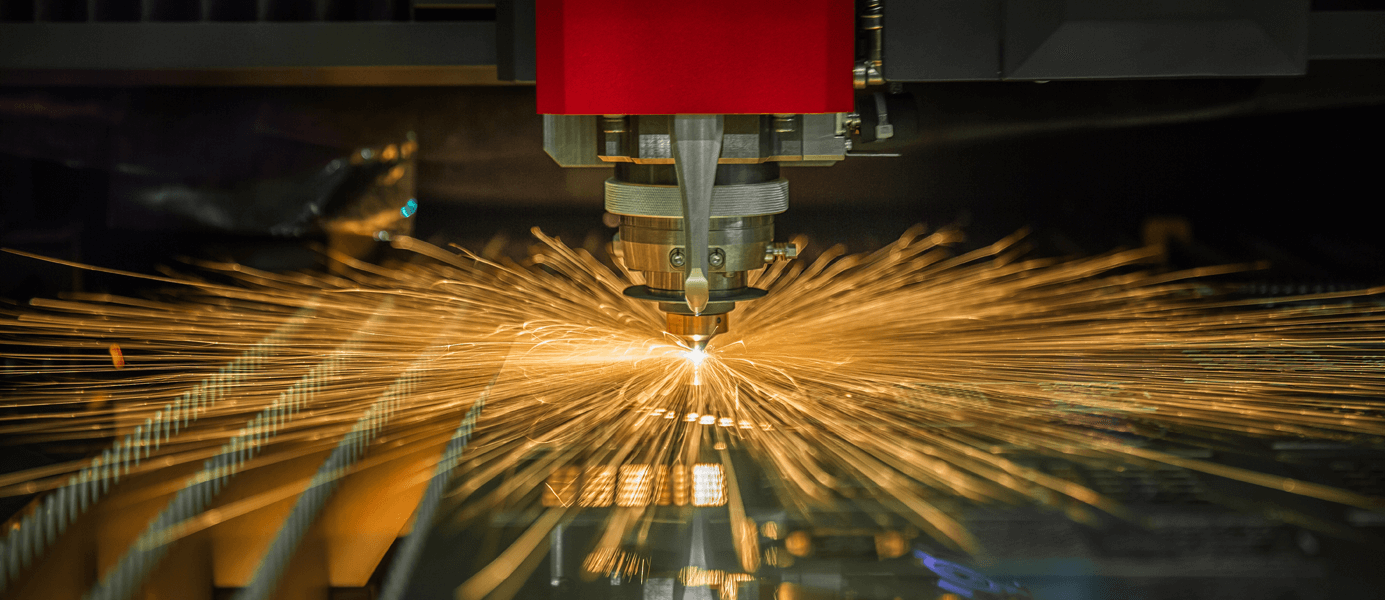

Advanced labs, fabrication facilities, and simulation tools

Flexible pathways + minors (Entrepreneurship, Industry 4.0, etc.)

Signature courses: 3D Printing, Nanomaterials, Robotics & Automation, Mechatronics

Drone Technology trainings aligned to industry needs

iScholars @ CMM + access to interdisciplinary research centers

Frequent industry-led workshops and masterclasses

Internships via SRiX & partner labs/industries; industry-guided capstone

Smart Manufacturing & Industry 4.0 (IoT/IIoT, AI/ML, Digital Twins)

Robotics, Mechatronics & Automation (PLC/SCADA, Control Systems)

Additive Manufacturing (3D Printing) & Advanced Manufacturing

Advanced Materials, Coatings & Surface Engineering

Energy Systems: Renewable (Solar/Wind), HVAC & Thermal

Automotive & Electric Vehicles (EV Powertrain, Battery Systems)

Transportation Systems: Railways, Highways & Mobility Engineering

Core Mechanical Domains: Design, Manufacturing, Materials, Thermal–Fluids, CAD/CAE

UAV/Drone Technologies & Applications

Innovation, Entrepreneurship & Product Development (SRiX, iScholars, CMM)

Smart Manufacturing / Industry 4.0 Engineer

Manufacturing / Industrial / Process Engineer

Automation & Controls Engineer (PLC/SCADA)

Robotics & Mechatronics Engineer

IoT/IIoT Solutions Engineer

Manufacturing Data & AI Engineer

Digital Twin / Simulation Engineer

Additive Manufacturing (3D Printing) Engineer

Advanced Materials & Coatings Engineer

Mechanical Design & Product Development Engineer (CAD/CAE)

Quality & Reliability Engineer

Maintenance & Asset Management Engineer

HVAC & Thermal Systems Engineer

Renewable Energy Systems Engineer (Solar/Wind)

Automotive / EV Powertrain Engineer

Battery Systems / BMS Engineer

UAV/Drone Systems Engineer

R&D Engineer

The Mechanical Engineering graduates from SR University, Warangal are expected to:

Program Educational Objectives (PEO) 1:Pursue a successful career in mechanical engineering through effective problem-solving, innovation, and industry-oriented skills

Program Educational Objectives (PEO) 2: Pursue higher education and/or professional development courses for life-long learning.

Program Educational Objectives (PEO) 3: Lead and support community building and economic development activities to improve the quality of life.

Program Outcome (PO) 1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization for the solution of complex engineering problems.

Program Outcome (PO) 2: Problem analysis: Identify, formulate, research literature, and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

Program Outcome (PO) 3: Design/Development of Solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for public health and safety, and cultural, societal, and environmental considerations.

Program Outcome (PO) 4: Investigate complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

Program Outcome (PO) 5: Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations.

Program Outcome (PO) 6: The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

Program Outcome (PO) 7: Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

Program Outcome (PO) 8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

Program Outcome (PO) 9: Inpidual and teamwork: Function effectively as an inpidual, and as a member or leader in perse teams, and in multidisciplinary settings.

Program Outcome (PO) 10: Communication: Communicate effectively on complex engineering activities with the engineering community and with the society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

Program Outcome (PO) 11: Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

Program Outcome (PO) 12: Life-long learning: Recognise the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Program Specific Outcome (PSO) 1: Materials and Manufacturing: Understand material properties' impact on design, select and test materials, choose effective manufacturing tools and techniques, and implement process planning and quality control to ensure product quality.

Program Specific Outcome (PSO) 2: Entrepreneurial Mindset: Demonstrate the ability to identify opportunities, realize innovative solutions, and structure business models to take them to the market.

Project-based curriculum which caters to industry needs. Students can participate in Hackathons, competitions & Maker-spaces to hone their practical skills. Workshops on industry relevant topics happen all the time

Flexibility to set your own schedule or the sequence of courses to tailor to your interests. You can also pursue minors in other departments

Cutting-edge industry relevant courses :

3D Printing Technology

Nanomaterials

Robotics & Automation

Mechatronics

Excellent award winning and caring faculty are available to you to help you learn new technologies and guide you in your career

iScholars program is available to help you become the next generation leaders. In the program, students learn by leading and promoting the student enrichment across campus.

Internship opportunities at SRiX as well as at partner industries and research labs

Courses designed to well acquaint students with latest manufacturing technologies.

Additive Manufacturing and Drone Technology trainings are emphasized to keep the students updated to meet the industry requirements.

Mechanical Engineers are required in all manufacturing facilities. There is tremendous scope for Mechanical Engineers in industries including

Design Sector

Manufacturing Sector

Power Sector

Automobile Sector

Aerospace

Material Development

Capgemini

TATA Motors

NTPC/BHEL/KTPP

DRDO

L&T

Thermax

Design Engineer

Manufacturing Engineer

Production Engineer

Thermal Engineer

Quality Engineer

Asst.Excutive Engineer/ Scientist/ Manager